New robot printer spits out recyclable robots

In just 13 minutes, a newly developed robot printer can transform an aluminum wire with little motors attached into a functional robot that can be recycled and reused for other purposes. Researchers from the IT University of Copenhagen (ITU), MIT and Columbia, among others, are behind the invention, which might eventually be used in space or in disaster situations.

Computer Science DepartmentResearchDigital Design DepartmentrobotsSebastian Risi

Written 3 July, 2017 07:14 by Vibeke Arildsen

Building a robot takes a long time and when the robot is finally finished, it can usually only be used for one single purpose. Inconvenient in situations where time is scarce and tasks may not be known in advance. In an attempt to solve these challenges, researchers from ITU, MIT, Columbia and Cornell have now developed a robot printer that in a matter of minutes produces simple, yet functional robots that can complete a variety of tasks.

See how the robot printer works in the video below.

www.youtube.com/embed/ElW0O2IiuXA

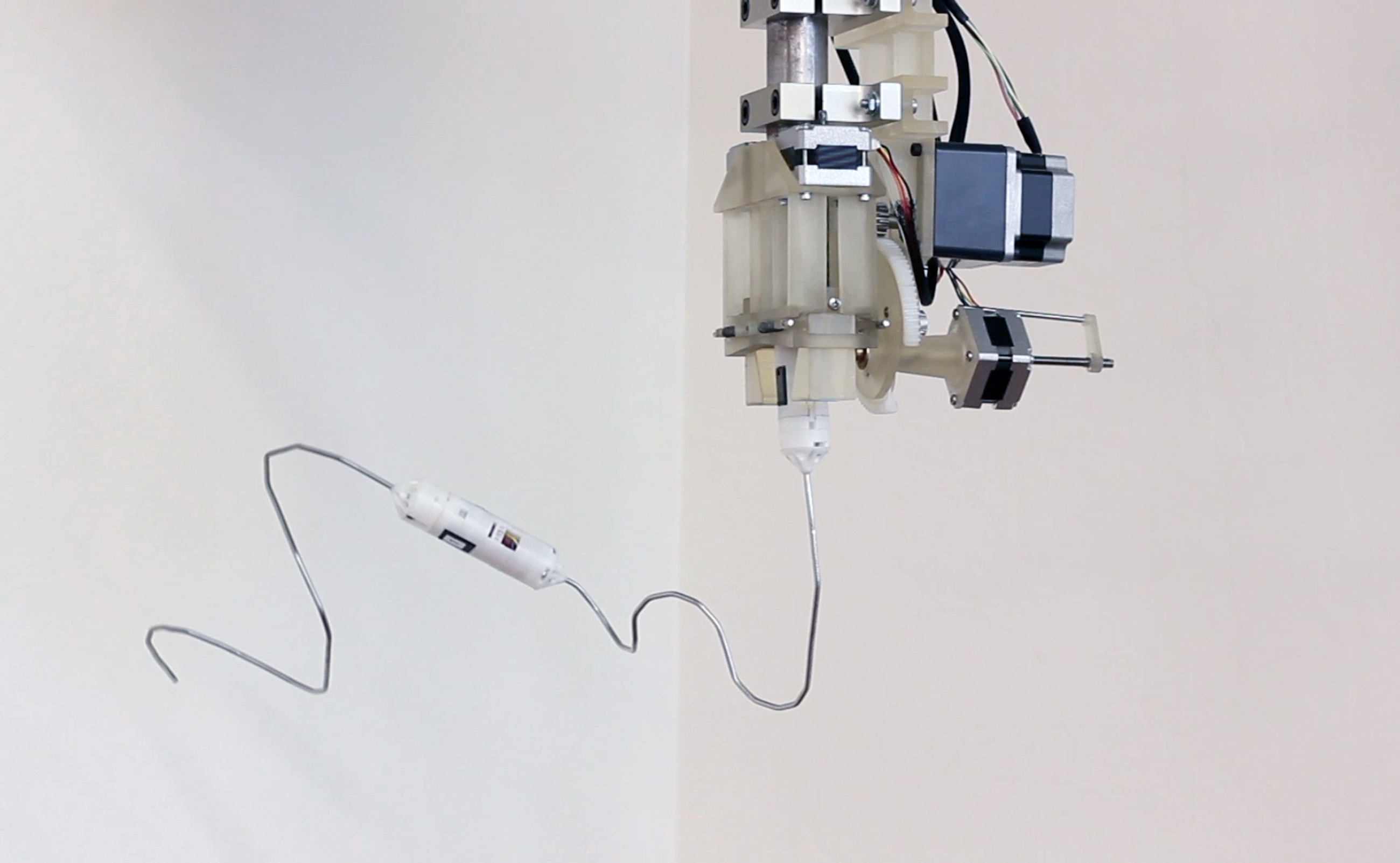

"We use a premanufactured material consisting of a one-dimensional aluminum wire with motors that are connected to each other. We then feed the wire to the printer, which then bends the material into a robot whose form determines the function. If the material is folded in a certain way, it will be able to crawl. If you fold it differently, it could potentially climb or roll. After use, you can simply flatten the robot, press a button, and print a robot with a new function,” explains Sebastian Risi, an Associate Professor at ITU.

Suitable for extreme conditions

The recyclability aspect could make the robot printer extremely suitable for use under extreme conditions, for example in space or in disaster situations, says Sebastian Risi.

"The robots are all made of the same source material. This would be practical for instance on a Mars mission where you might first need a robot that can climb, and later need a robot arm that can grab an object. The robot printer can also be used in situations where you do not know in advance what type of robot you will need, for example in connection with disaster recovery."

The robot printer has not yet been tested outside the lab, but Sebastian Risi and his American colleagues are planning to develop it further so that it eventually will be able to build complex and hardy robots that can be used in the real world.

"We need to add sensors and cameras and find a material more stable than aluminum that can be bent many times without deforming," he says.

Biological inspiration

Despite being a high-tech product, the robot printer actually draws inspiration from the biological world.

"The way in which it folds one-dimensional material into complex 3D formations is inspired by the ribosome, which is the machinery in all biological cells responsible for protein synthesis. The ribosome enables the construction of the countless number of chemicals that form the basis of all cells through the assembly of amino acids. In a similar way, the robot printer uses a one-dimensional material that can be reused to build a variety of different and specialized robots," says Sebastian Risi.

The robot printer bends the one-dimensional aluminum wire into robots with different functionalities.

The algorithm that creates the robot designs is inspired by another biological phenomenon, evolution.

"To find the optimal way to bend robot material, the computer simulates an evolutionary process where it tests a lot of different shapes and then finds the best shape to perform a particular task. One simply tells the printer to make a robot that rolls forward, then it finds the best design itself, without any human telling it how to do it," he says.

Sebastian Risi, Professor, email sebr@itu.dk

Vibeke Arildsen, Press Officer, phone 2555 0447, email viar@itu.dk